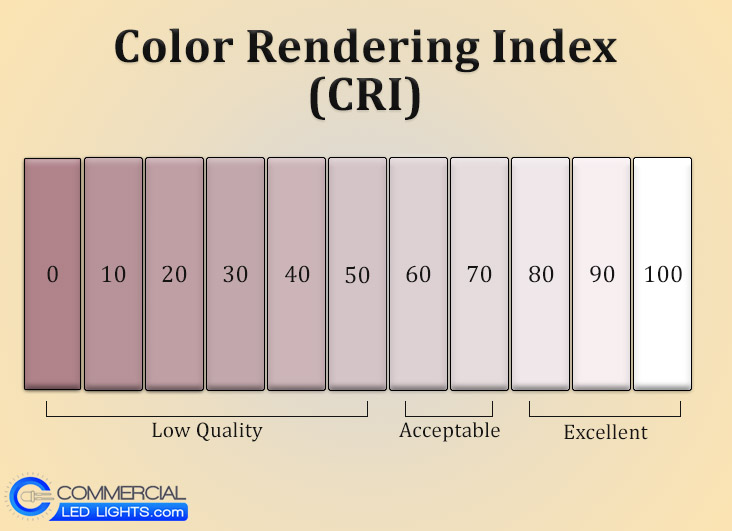

The accuracy of lighting is of particular importance in today’s residential, commercial and industrial markets. This is measured and quantified using the Color Rendering Index (CRI), which is the industry standard for measuring a particular light’s accuracy. CRI runs on a scale going up to 100, which is the CRI of a black body radiator reference light. This reference light is either an incandescent type artificial light or natural sunlight, which are the most accurate light sources available. It is worth noting that CRI is independent of Coordinated Color Temperature (CCT), which is a term that is often used in conjunction with CRI when describing the properties of a light. CCT measures the actual color of the light produced in Kelvins and does not have anything to do with the lights illumination accuracy.

Lighting accuracy was not very well studied by color scientists prior to the advent of fluorescent lighting, as all forms of common lighting were very close to natural sunlight. With the advent of newer more efficient lighting technologies such as fluorescents, HIDs and Sodium Lamps, concerns were raised about the illumination accuracy of these newer artificial lights. This sparked interest into lighting accuracy and by the mid 20th century, extensive research had begun that explored the abilities of artificial light to reproduce colors accurately.

The primary organization that oversaw this research and the subsequent development of measurement standards was the International Commission on Illumination, which is also known as the CIE from its French title (Compagnie ivoirienne d’électricité). The CIE was formed in 1900 with the primary goal of promoting cooperation and exchange of information on all matters regarding the science, technology and the art of lighting. The CIE began work in the 1960’s to develop CRI measurement procedures and standards, which over several decades resulted in an extensive body of research. This culminated in the creation of the CRI measuring method used today known as CIE (1995), which is the global industry standard for measuring the accuracy of an artificial light.

Definitions

CRI – Color Rendering Index – This is the measurement scale used by color scientists to measure a light’s accuracy in illumination. CRI runs on a scale of up to 100, which is the CRI of an incandescent light or natural sunlight and considered a perfect score and. The higher the CRI, the more accurate or better quality illumination a light provides. Here’s a comprehensive article on CRI illumination that covers this topic in greater detail.

CIE – International Commission on Illumination – The commission formed for the purpose of studying the technology, science and art of lighting. Meets periodically in order to develop new standards as well as improved scientific methods. The CIE is responsible for the creation of the CRI measurement standard and continues to update and improve upon this over time.

CCT – Coordinated Color Temperature – Independent of CRI, this is the measurement of a lights actual color using Kelvins. The higher the CCT, the more “blue” a light becomes, whereas the lower the CCT the more “yellow” a light becomes. For reference, natural daylight has a CCT of around 5000 kelvin and most artificial lights tend to hover around this color temperature.

ColorChecker Chart – A standardized color calibration target used for testing color rendering accuracy. It contains multiple squares painted with color samples which are referenced against light(s) being tested. This chart is critical for the color rendering index measurement process.

Fluorescent Light – Historically ubiquitous type of light used in residential, commercial and industrial realms. This low pressure mercury vapor gas discharge type lamp produces light by running electricity through mercury vapor contained a phosphorus coated sealed tube. These lights were popular for years due to their energy efficiency.

Incandescent Light – This is the original type of artificial light, used for over one hundred years in every conceivable lighting application worldwide. Incandescent lights generate their illumination by the pumping of electrical current through a tungsten filament. These are still used today due to their exceptionally low initial costs and their ease of installation.

LED Light – A relative newcomer to the lighting industry, LED lights have become the dominant form of illumination for all types of applications and industries over the past decade. LED stands for “Light Emitting Diode”, which is a semiconductor light source that produces light when electrical current flows through it. LED lights are popular due to their energy efficiency, high CRI ratings, low maintenance and long lifespan.

How does CRI Work?

CRI is measured using the industry standard method developed by the CIE. This involves the comparison of a test source’s color rendering to a reference source known as a black body radiator with a perfect CRI score of 100. For this testing, there are ten primary reference samples used to calculate the general CRI rating. The sample selected for the reference source is dependent on the color temperature of the light being tested. The ColorChecker chart, established by CIE (1999), categorizes these reference sources and organizes them numerically starting with TCS01 and ending with TCS10. The closer the source being tested matches with the perfect reference source, the higher it will rank in CRI.

CRI ratings for artificial illumination will vary depending on the type of light used. Incandescent lights, as previously mentioned, provide the equivalent CRI rating as natural sunlight, which is 100. This is the optimal CRI rating that all other artificial light sources seek to achieve. Sodium lamps achieve the lowest CRI ratings across the board, with an effective CRI ranging from nearly zero for low pressure types. HID lamps have the ability to produce CRI ratings of up to 60 in optimal conditions, however as they age their CRI ratings decrease noticeably.

Fluorescent lights, which have been the most popular choice of lighting for decades throughout the world, have an average CRI rating of 70. While this is a significant improvement over HIDs, it is far from optimal. The highest CRI ratings seen in artificial lighting currently are in LED lights, which have an average CRI between 80 and 95. While there are always exceptions to these generalizations, they should be considered to be accurate representations of the CRI ratings of different lights and what one should expect when using them.

The Importance of CRI

It should be clear now that CRI is a vital measurement for determining the performance of an artificial light and is a key purchasing consideration in today’s lighting market. Building managers, decision makers and purchasers have come to recognize the important benefits of using lights with higher CRI ratings. This includes not only an improvement in workplace safety, but also the productivity and efficiency of a commercial environment. These benefits are most noticeable with lights having a CRI of 80 or above, which is considered good for general commercial and industrial purposes.

The most readily apparent benefit of lights with higher CRI ratings is the improvement in safety as a result of increased visibility. Lights with lower CRI ratings such as sodium lamps and fluorescent lights do not accurately show true colors, which makes distinguishing between colors difficult. This can affect the ability to read or notice things such as warning labels, safety zoning, or other important safety related information such as bright colors to draw attention to risks and danger. Improvements in visibility due to a higher CRI light source such as LEDs reduces these risks and the number of accidents, mistakes and related issues.

Productivity is another benefit of higher CRI lighting which is often overlooked on paper. A workplace illuminated with a high CRI lighting produces a far more pleasurable environment for workers and employees. Higher CRI ratings reduce stress, headaches, tension, depression, eye strain and improve overall mood, all of which boosts productivity. This improvement is especially notable over time due to its direct impact on a company’s bottom line and profitability.

In the retail world, lighting with a high CRI has the additional benefit of improving sales performance. Customers shopping retail stores prefer high CRI lighting, for the same reasons as employees and workers as mentioned previously. There is such a preference for this that retail locations who have switched to high CRI lighting have seen significant improvements in sales numbers afterwards. This is due to not only a more pleasurable shopping experience, but also the improved illumination of products which increases their appeal.

CRI in Summary

The numerous benefits of high lighting accuracy have made it a top priority for customers in today’s marketplace. The one of the immediate benefits is a significant improvement in the quality of life for customers, employees and other users due to the improved color rendering which eases eye strain and overall stress levels. An additional benefit for business owners and operators is a reduction in workplace accidents and an improvement in efficiency as a result of increased visibility.

Out of the entire spectrum of artificial lighting, LEDs are now the primary choice for those seeking the best color rendering. Because of this, most lighting manufacturers are exclusively using LEDs in their fixtures due to not only their impressive CRI ratings but also because of their energy efficiency. As this technology continues to evolve and improve, commercial and industrial business customers have a bright future to look forward to.