For decades, tube lights have provided excellent illumination capabilities for a variety of commercial and industrial environments, from office spaces to warehouses and workshops. Their versatility is one of their biggest selling points, as the fixtures they are mounted in can be hung, suspended in a drop ceiling or even mounted directly to a flat ceiling surface. Additionally, they are inexpensive to install and operate, which when combined with their strong lumen output and wide angle of spread, makes them one of the most popular lighting options in the lighting industry.

In this guide we will be focusing on the specifics of LED tube lights, including the wide variety of options available in today’s marketplace.

— Navigation —

- LED Tubes v.s Fluorescents

- LED Tube Sizes

- Tube Types

- Direct Wire Tubes

- Ballast Compatible Tubes

- Hybrid Tubes

- Universal Ballast Compatible

- Color Temperatures

- Wattage Selection

- Installation

LED Tubes v.s Fluorescent Tubes

Traditionally, these tube lights have been of the fluorescent type, which uses low-pressure mercury-vapor gas discharge technology to generate light when electricity is passed through it. While this served many businesses well for decades, it is now considered outdated, inefficient and even environmentally hazardous due to the mercury contained within. As the fixtures themselves age, they also require additional maintenance, such as the replacement of the ballasts required to run the lamps. On top of all of this, the light produced by fluorescent lamps is regarded as subpar, with a consistent flicker from the light switching on and off at approximately 120 Hz that causes eye strain over long periods of time.

It is for the aforementioned reasons that LED tubes have come to completely dominate the lighting marketplace for new installations as well as the retrofit of existing fixtures. LED technology in tube lights resolves all of these concerns, and also adds some additional welcome benefits. When used in tube lights, LEDs offer a longer lifespan, are more energy efficient, contain no toxic substances and also produce a much higher quality of light with less eye strain and greater visibility thanks to their high CRI ratings.

Tube Sizes

There are a variety of shapes, lengths and diameters in tube lights in order to suit a wide range of applications. Generally speaking, with LED tubes the most common size and shape are the 4 foot length fixtures with a T8 diameter. Other lengths available in the marketplace include 2 foot, 3 foot and 8 foot. In the past, T12 diameter bulbs were the standard, eclipsed first by T8 and then T5. For older fluorescent fixtures, the most common setup is going to be either a T12 or T8 type due to the costs associated with running T5 fluorescent light fixtures.

When upgrading older existing fixtures, sometimes the issue arises where it is unclear what diameter bulb is currently installed. Luckily, this is an easy fix as the labeling system is standardized across all manufacturers. The “T” stands for tubular, referring to the bulb’s shape, and the number following it represents the bulb diameter in eighths of an inch. This means a T8 bulb will be 1” in diameter, while T12 and T5 bulbs will be 1.5” and ⅝” in diameter respectively. It should be noted that as long as a T8 and T12 are using the same pin base (G13 most likely), they can be used interchangeably, as long as they are within the same milliamp requirements for the ballast if it is using one.

Below is chart that illustrates the various sizes and base types for tube lights:

Tube Types

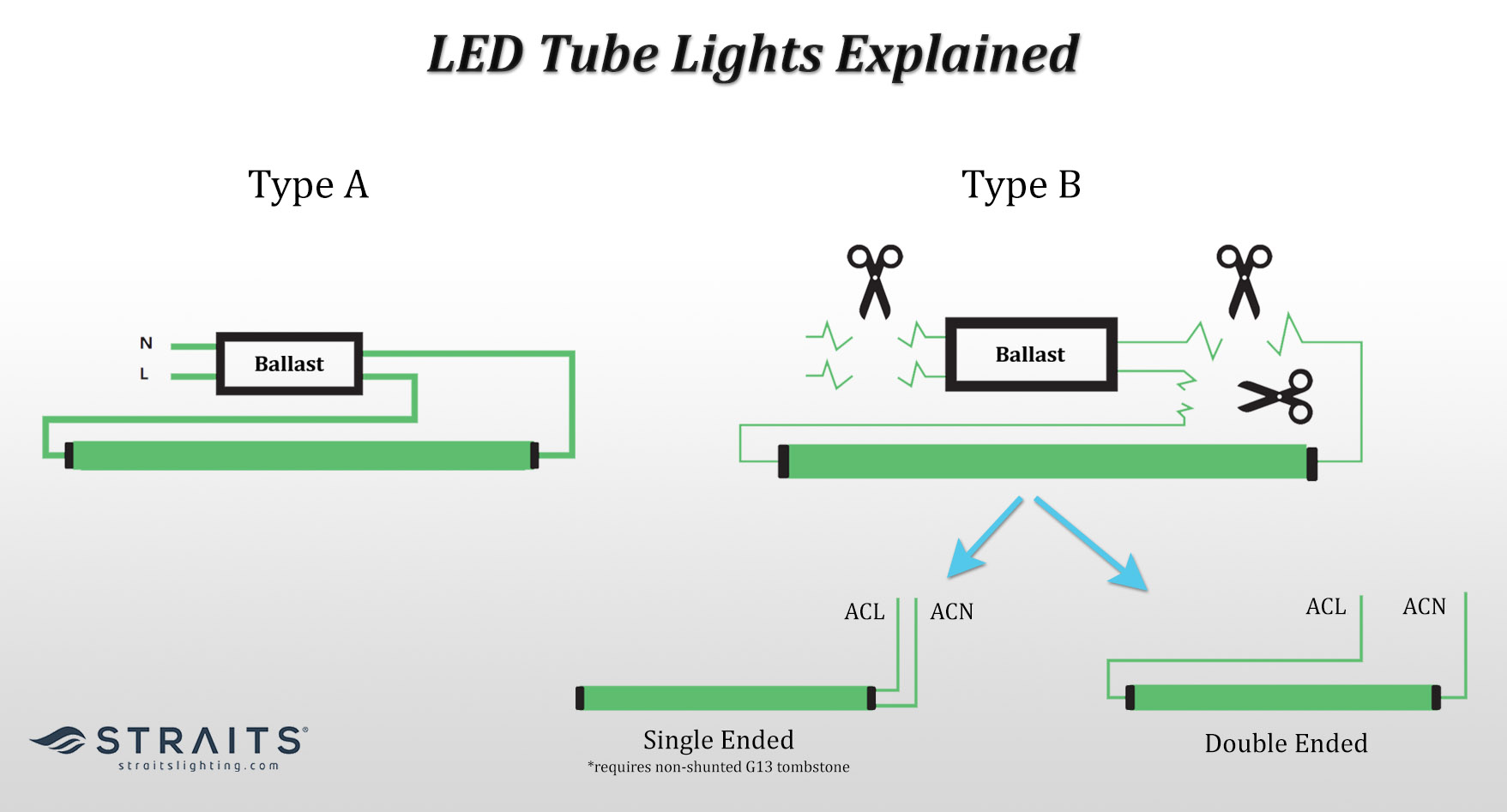

There are four different types of LED tubes available on the market today, which can be confusing for buyers, especially those who have never shopped for LED lights before. Most of what differentiates these tube types from each other depends on whether it uses a ballast or bypasses it, as well as whether it uses single or double ended wiring. The main types are Direct Wire (also known as ballast-bypass or Type-B), Electronic Ballast Compatible, Hybrid, and Universal Ballast Compatible.

Direct Wire Tubes

Direct wire tubes are by far the most straightforward, in that they bypass the ballast completely and run directly off line voltage. Not requiring a ballast offers a significant advantage in cost savings throughout the fixtures lifetime, as there is no longer the requirement to replace expensive ballasts that periodically fail or wear out. This really comes into play with big installations such as warehouses and multi-story office buildings, as cost savings per fixture can add up quickly with a large number of fixtures.

Something to keep in mind with direct wire fixtures is that they may require some additional parts to complete retrofitting. Tube lights use “tombstone” sockets to power and hold the bulb, and there are two main types of tombstones used in the lighting industry – Shunted and Non-Shunted. For direct wire fixtures, non-shunted rapid start tombstones are required for proper operation. If the existing fixture is a T12 type, then it should already have the correct tombstone type already installed.

However if it is a T8 type fixture, then the input tombstone sockets will need to be changed over to the Non-Shunted Rapid Start T12 style sockets in order to work properly. This is due to a circular connector in T8 sockets that doesn’t allow them to separate the line or circuits neutral sides properly. Even though this is a pretty straightforward process, it is recommended that a qualified and licensed electrician complete this task since it involves some rewiring. For commercial properties, the use of the correct tombstones is required.

Electronic Ballast Compatible Tubes

Commonly known as “Type-A” or “Plug-n-Play” tubes, electronic ballast compatible tubes are a relatively new addition to the tube lighting marketplace. As suggested by the name, these lights are designed to work with existing tube fixtures equipped with electronic ballasts. Because of this, these lights will not function if installed in fixtures that contain magnetic ballasts or no ballast at all. Because the last generation of fluorescent fixtures exclusively used electronic ballasts, these tubes are becoming one of the most common types sold that work with existing fixtures, and will likely increase in popularity as existing fixtures continue to be retrofitted with LED technology.

These types of bulbs are straightforward to install as they simply require replacing the old fluorescent tube with a new LED tube. Because there are so many different electronic ballasts on the market, LED tube manufacturers have gone through extensive testing to ensure that their electronic ballast compatible tubes will work regardless of the ballast manufacturer. This takes out the guesswork for buyers and makes installation as easy as possible.

While this is great from an ease of use standpoint, it usually results in these tubes having a higher initial cost. On top of this, if the ballast fails then the tube will no longer illuminate which adds to the potential long term costs of this type of LED tube lighting setup. Because of this, ballast compatible tubes usually are only installed on small scale applications where ease of installation is a priority and the relatively low number of ballasts powering the tubes does not present as much of a financial risk.

Hybrid Tubes

Known as “Type A+B”, these tubes are unique in that they offer compatibility with fixtures using ballasts as well as those that do not. The closest thing to a “one-size-fits-all” tube, hybrid tubes take the guesswork out of bulb selection and have become a very popular choice in the tube lighting marketplace. They have the capability to be used with existing electronic ballasts and also can be directly wired for those who prefer it.

This gives flexibility to users, especially those who have both T8 and T12 type fixtures in a building that may require both types of wiring to complete installation. It also gives users the option to quickly and easily upgrade their ballast equipped fixtures to LED technology while giving them the option to switch to direct wiring in the future if the ballast were to fail. This saves the hassle of having to replace the ballast or make the switch to a dedicated direct wire type of tube.

Universal Ballast Compatible

The newest type of tube on the market, universal tubes are the easiest to install of all types and are also the most expensive. Unlike Hybrid and Type-A types of tubes, universal tubes are compatible with both the magnetic ballasts found in T12 fixtures as well as newer electronic ballasts found in T8 fixtures. This is a very popular option for smaller projects such as retail stores, workshops and homeowner applications whose primary purpose for upgrading to LED technology is to reduce energy consumption while minimizing downtime during installation.

One of the downsides to universal ballast tubes is their higher initial investment costs per unit. In fact, universal tubes are some of the most expensive of all of the four major options on the market today. In addition to this, there are still the maintenance concerns associated with ballasts, and since these tubes are only designed to be used with ballasts they cannot be direct wired in the event that a ballast fails. This is of especial concern when they are used in older fixtures using magnetic ballasts such as T12 style units where replacement ballasts are no longer available.

Color Temperatures

After selecting the correct size and type of tube, buyers will have multiple options for color temperature ranges. Color temperature is the hue or color of the light produced, and is measured using the Kelvin (K) scale which usually ranges from 2400K to 6500K. In the LED lighting marketplace, the typical color temperatures available are normally 2700K, 4000K, 5000K and 6000K.

The lower the color temperature, the warmer or more red the light becomes. On the opposite end of the color temperature range, the light becomes white and then blue in its hue. For offices and general workspace use, the 4000K range is one of the most popular, with a “cool” white color. For areas requiring a daylight equivalent such as high-security areas, garages, parking structures, private roads, alleyways and general display areas, 5000K is the top choice.

Below we have included a chart that details these different color temperature ranges and their applications:

Wattage Selection

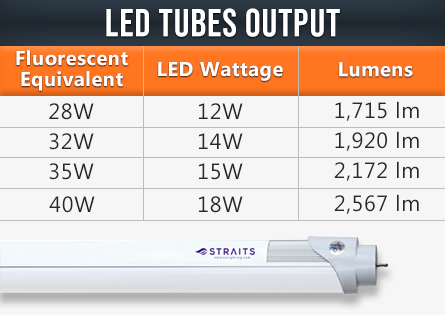

One of the most confusing things for buyers new to the LED marketplace is determining the correct wattage for their application. This is due to the fact that LED lights require a fraction of the energy used by traditional lighting technologies such as fluorescent to produce the same amount of light, measured in lumens. In general, when trying to choose the appropriate LED light wattage for an application, it is best to instead determine the lumen output required. Once the lumen requirement is determined, the correct LED bulb that meets that requirement can be selected.

Because most users do not know and do not have any practical way of determining the lumen output of their existing fluorescent lighting, we have created the chart below that compares the lumen output of traditional fluorescent tubes with LEDs:

Installation

While installation in most cases is pretty straightforward, there is the possibility that rewiring will be required, such as with direct wire tubes. Because of this, we strongly recommend working with a licensed electrician experienced in LED retrofitting. This will not only ensure the best lighting performance but also make certain that the installation was completed safely. The best way to find an electrician is via a directory, which can be narrowed down by state or province, depending on whether the installation is in the United States of Canada. Below are a couple of directories that can help in this search:

United States:

Electric Contractors Directory